Levelling feet / machine feet

What are levelling feet?

Levelling feet are used in industry to stabilise and optimally position machines. The machine feet are not only used to compensate for uneven surfaces. They also fulfil important functions such as vibration damping and load distribution.

Machine feet are made from robust materials such as stainless steel or electro zinc-plated steel. The materials are often combined with rubber elements that absorb vibrations and provide a non-slip base.

Their diversity enables levelling feet to be used in numerous application fields. In machine and plant construction they enable e.g. the levelling of production equipment. In the furniture industry, they ensure that pieces of furniture have a secure stand.

What are levelling feet used for? Structure and function of levelling feet

The KIPP product range

Advantages of KIPP levelling feet

What are levelling feet used for? Structure and function of levelling feet

Levelling feet are used to safely stabilise and align machines or appliances and, if necessary to dampen vibrations . They compensate for floor unevenness and enable precise levelling, which is particularly important in industry and machine construction.

In industrial applications, such as CNC machines, production equipment or conveyor belts, machine feet ensure that machines can be precisely adjusted. This ensures optimum functionality and durability.

Levelling feet are also used in less demanding areas. For furniture, shelving or laboratory benches for example, to ensure stability and compensate for uneven floors.

They are therefore a versatile component for stability, alignment and protection in various environments.

A levelling foot consists of two main components, a threaded spindle and a foot.

The spindle is a rod with an external thread that permits the height of the levelling foot to be precisely adjusted by rotating it. To withstand high loads these are made from robust materials such as stainless steel or steel.

The foot, also known as a plate or foot plate, forms the support element and provides stability. Made of stainless steel, steel, thermoplastic or zinc, the foot plate also offers slip resistance and vibration damping.

Are you looking for a threaded spindle or a plate? Feel free to browse through our range.

The KIPP product range

As they are available in a wide range of materials, KIPP levelling feet are very versatile. The materials used are a very important criterion and should definitely be taken into account when selecting a levelling foot. We also offer swivel feet, swivel pads and accessories for levelling feet. In the following, however, we look at the major products in the levelling feet and machine feet category in the KIPP range.

Steel or stainless steel levelling feet

The steel or stainless steel levelling feet are a combination of a spindle and a foot plate. Depending on the version, the threaded spindle is either made of electro zinc-plated steel or bright stainless steel. Stainless steel type 1.4301 is used.

The foot plate is available in polished stainless steel or electro zinc-plated steel.

Steel feet are suitable for applications with a higher load on the levelling foot. Steel is a very robust material, so signs of material fatigue are unlikely. This in turn increases process reliability. Due to the material properties, levelling feet made of steel are primarily suitable for dry indoor areas.

Stainless steel feet are characterised by their high load-bearing capacity and great flexibility. Stainless steel machine feet are just as robust as steel feet. However, they are also very corrosion resistant.

Stainless steel levelling feet are therefore suitable for use outdoors as well as in damp indoor areas.

Another important component of machine feet is the NBR rubber base. The rubber base has a hardness of Shore 80 and is permanently attached to the sheet metal plate. It offers excellent grip. In addition, the rubber material is not only non-slip but also sound-absorbing. This reduces the transmission of vibrations and shocks to the floor.

Levelling feet in Hygienic DESIGN

Levelling feet in Hygienic DESIGN are indispensable operating components for foodstuff and pharmaceutical industries. In both sectors, it is of the utmost importance that the machine feet fulfil hygienic requirements. The surfaces of the machine feet are particularly smooth. This prevents the build-up of dirt and micro-organisms and simplifies cleaning.

Dispensing with unnecessary screw connections and minimising cavities and corners also ensures that germs cannot settle in hard-to-reach corners. This significantly reduces the risk of contamination. These properties make these operating parts the ideal choice for sensitive industrial sectors.

Customer favourites:

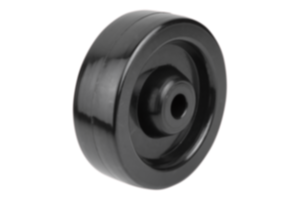

Height-adjustable levelling feet

Height-adjustable levelling feet are used wherever equipment needs to be levelled. They are made from a robust fibreglass reinforced thermoplastic housing and an electro zinc-plated steel hex head screw. The steel screw ensures high stability and durability of the operating parts. The housing is finished in an elegant black and provides a robust base, while the hex head screw enables precise height adjustments.

The flat end part and the recessed hex head screw enables the height-adjustable levelling feet to be particularly suitable for mounting on smooth surfaces.

The height can be infinitely adjusted by turning the nut by hand or using a tool. This enables simple and flexible adjustment. In addition, the feet protect the floor, reduce vibrations and ensure a secure stand, even on uneven ground.

Vibration dampening levelling feet

Levelling feet with vibration absorbers are used to install machines safely and stably while at the same time reduce vibrations. They offer considerable advantages, particularly in environments with high dynamic loads such as machining or for laboratory equipment.

The vibration-absorbing properties are achieved through special materials and designs. The elastomer material absorbs vibrations generated by machines and prevent them from being transmitted to the floor or neighbouring systems. This not only reduces noise, but also minimises wear on the machines.

Advantages of KIPP levelling feet

The levelling foot range from KIPP includes machine feet and levelling feet. They offer numerous advantages that make them popular in industrial and commercial applications. We have listed the key advantages of KIPP levelling feet below.

- Height adjustability: Enables precise levelling of machines, worktops or shelving for stability and safe operation.

- Robustness and durability: Made from high-quality materials such as stainless steel or electro zinc-plated steel, they are particularly durable and resilient.

- High load capacity: Suitable for high loads, ideal for machines and industrial applications. Four levelling feet can support up to 12 tonnes.

- Vibration and noise insulation: Equipped with buffer elements that make operation quieter and more efficient.

- Corrosion resistance: Variants made of stainless steel or with special coatings are suitable for damp or aggressive environments such as the foodstuff or chemical industries.

- Simple installation: Easy to fit and adjust, often without additional tools.

- Flexibility: Different foot plates, such as with rubber base or non-slip coatings, enable use on different floor types.

- Versatility: Available in numerous sizes and versions, for applications ranging from light furniture to heavy machinery.

- Aesthetics and design: Clean finish and attractive design, also ideal for offices or salesrooms.

- Safety: Stabilisation and levelling minimise the risk of tipping or vibrations and increase safety in the workplace.

- Individual adaptability: KIPP offers the option of developing tailor-made special solutions that are specifically suited to your machines or applications.

A large selection of levelling feet in various designs awaits you in our online shop. These can be perfectly suited to your individual requirements.

Find the ideal swivel foot for your application - precise, robust and flexibly adjustable.

If you do find the appropriate model, we will be happy to develop a customised special solution for your machine or application.